Steel Mills Increase ROI With Energized Motor Testing

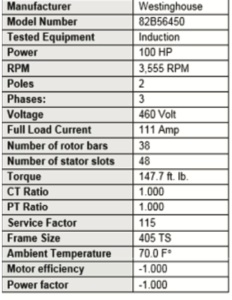

If a steel mill was at risk of losing $5,000 for every minute of unplanned downtime, it would be no surprise to see that steel mill implement a preventive maintenance program to keep their equipment running reliably to avoid unscheduled shutdowns. One American steel manufacturer who understands the importance of preventive maintenance sends their team of motor techs to test motors throughout the steel production facility every 6 months. In April 2014, one motor tech detected a fault in a 100-horsepower Westinghouse AC motor after using the ALL-TEST PRO On-Line II™ energized motor testing instrument.

Understanding the Application

This 100HP motor was one of many motors that operated in the #3 Coil Strip, where steel coil is processed through the #3 CAL (Continuous Annealing Line). The annealing line unwinds the steel coils, heats them up to a malleable temperature, and sends it through various processes to achieve specific qualities.

“There are lots of moving parts in a steel plant,” explains Frank Settles, Steel Mill Motor Tech. “When I go out to test motors on a route, I’m testing at least 25 motors at a time.”

Settles connected the portable, hand-held ATPOL II™ energized motor testing instrument to the electrical panel in order to conduct the condition monitoring tests at a safe distance from the operating motor. “When I tested this 100HP motor, the ATPOL II™ indicated there was an issue with the rotor bars,” states Settles.

The abnormal indications were reported to the department head of the #3 coil strip, and immediate action was taken to replace the motor. Once a new motor was installed in the #3 Continuous Annealing Line, the motor with questionable health was then sent to a Midwestern motor repair facility for further inspection and analysis. The steel mill’s maintenance manager wanted the motor repair facility to check the condition of the motor and confirm the results of the energized motor test.

Further Investigation Confirms ATPOL II™ Test Results

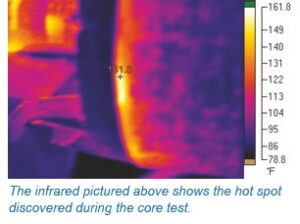

At the motor repair facility, several tests were performed: the 100HP motor showed initial Meg-ohm readings of 200+ at 500-Volts; the surge test was acceptable. Then the rotor was core-tested to look for shorts in the laminations as well as shorts in the connections between the laminations and the grounding ring.

“A hot spot was discovered in the laminations near the short circuiting ring,” explains Jonathan Walma at Harrison Electric, Inc. “The rotor bars have current induced into them from the stator to create a magnetic field. When one of these bars is disconnected, the horsepower that the motor provides is reduced and the current required to operate the motor at full loads increases, so it was a good pull; otherwise the motor would have put itself in an overload situation.”

After the motor repair shop confirmed the rotor issues initially detected by the ATPOL II™, the steel mill’s maintenance manager compared the cost to repair the motor with the cost to purchase a brand new motor. Seeing that the cost to repair the motor was greater than the cost of a new motor, the maintenance manager requested the faulty motor be returned to the steel mill for proper recycling and disposal.

“The steel mill did not suffer any losses because the rotor faults were detected prior to failure,” exclaims Settles. “The ATPOL II™ has been great for fi nding faults with both AC and DC motors, and I’ve even been able to project ‘down the road’ when there might be an issue with a motor. One time, we had third-party testers come in with different equipment – very expensive, not portable like the ALL-TEST Pro instruments – and they didn’t pick up the issues that the ATP equipment could.”

Make Motor Testing Part of Your Preventive Maintenance Program

To date, this steel mill has acquired about $80,000 worth of motor testing equipment from ALL-TEST Pro – both energized and de-energized testing instruments. They have regularly upgraded their software, calibrated their equipment, and utilized the on-site and remote support provided by ALL-TEST Pro. This steel mill has made an extensive effort to perform motor testing as part of their preventive maintenance program, and it has resulted in major savings. So can energized motor testing save every steel mill $7 million per day? While that is a hard question to answer, one thing is for sure – downtime costs money. When equipment fails, it is represented in real dollars every time a production facility stops operating. Make motor testing part of your preventive maintenance program to keep your motors up and running, then calculate the savings.

Watch this video to lean how motor testing can save you time, money, and headaches. Visit alltestpro.com for more information.

About ALL-TEST Pro, LLC

ALL-TEST Pro delivers on the promise of true motor maintenance and troubleshooting, with innovative diagnostic tools, software, and support the enable you to keep your business running.